Skip to:

Bring Out the Best

America's #1 Mayonnaise is made with real, simple ingredients to bring out the best in all your meals.

- slide 1

- slide 2

- slide 3

- slide 4

- slide 5

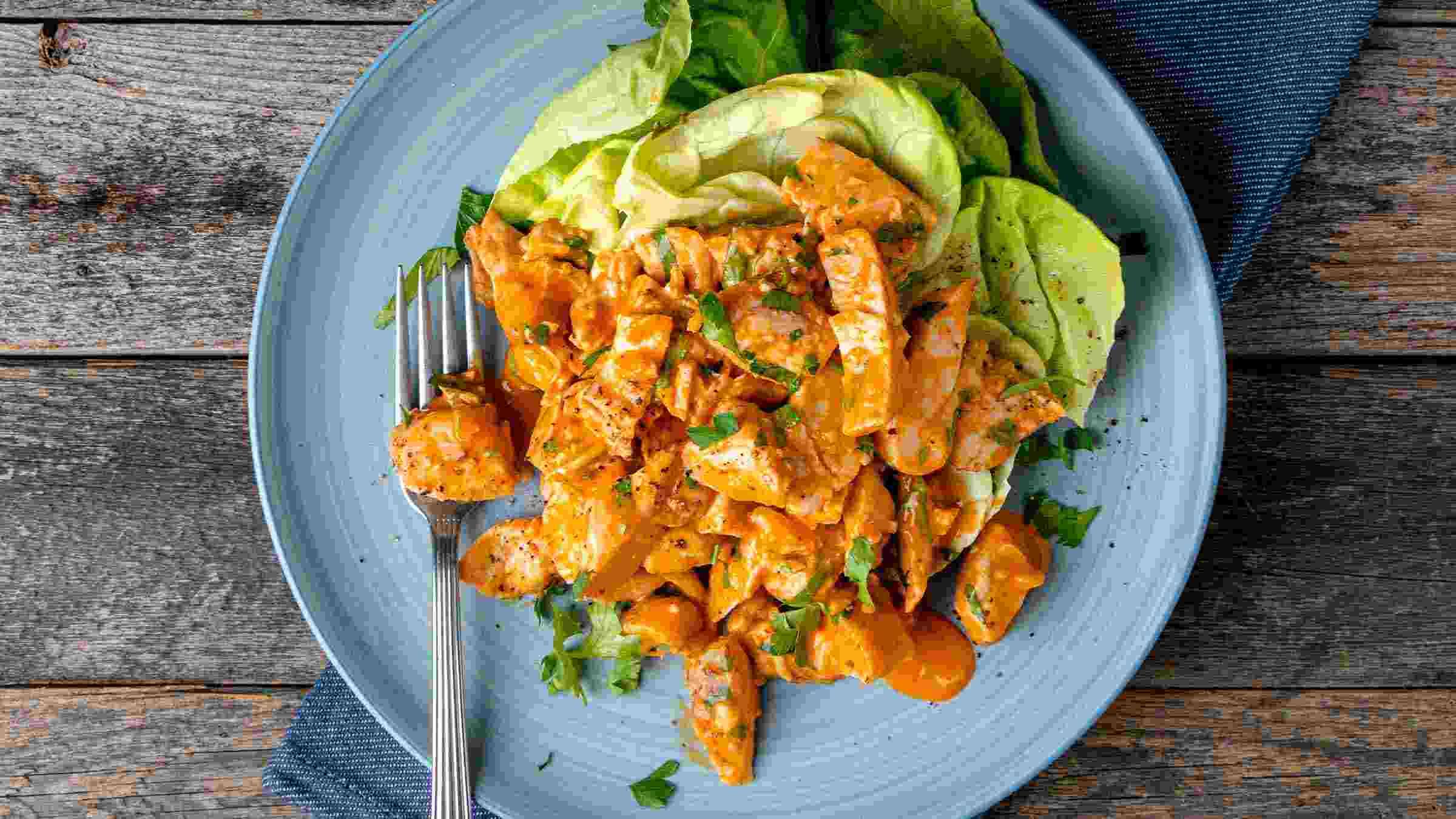

Let Your Inner Chef Shine

With more than 400 recipes, let Hellmann's inspire your next dish.

From Our Kitchen to Yours

From Hellmann's chefs to your home, learn new techniques and test new recipes.