Skip to:

At Hellmann’s we are standing up for fresh tasty food, and where it comes from.

As the leading mayonnaise brand in the US, we have the responsibility to provide the people who love our products with condiments that not only taste good, but are a force for good. Put simply, we believe in Real Taste and Less Waste, that’s why we’re committed to tackling the packaging waste of our products. Discover the overall plastics problem, what we are doing about it and what you can do to help below.

The global plastics problem is a wrong we have to right. Whilst plastic has many great qualities, current methods of manufacture mean a lot of products are only made from single use plastic. There is no clear guidance on how and where to dispose it, and the infrastructure for recycling in many countries is not in place to reincorporate this material back into production. As part of a wider initiative from Unilever, Hellmann’s is progressively making its packaging recyclable, however, the issue globally is way bigger than just one company, the issue lies within plastic itself.

Recyling problems that industries face today:

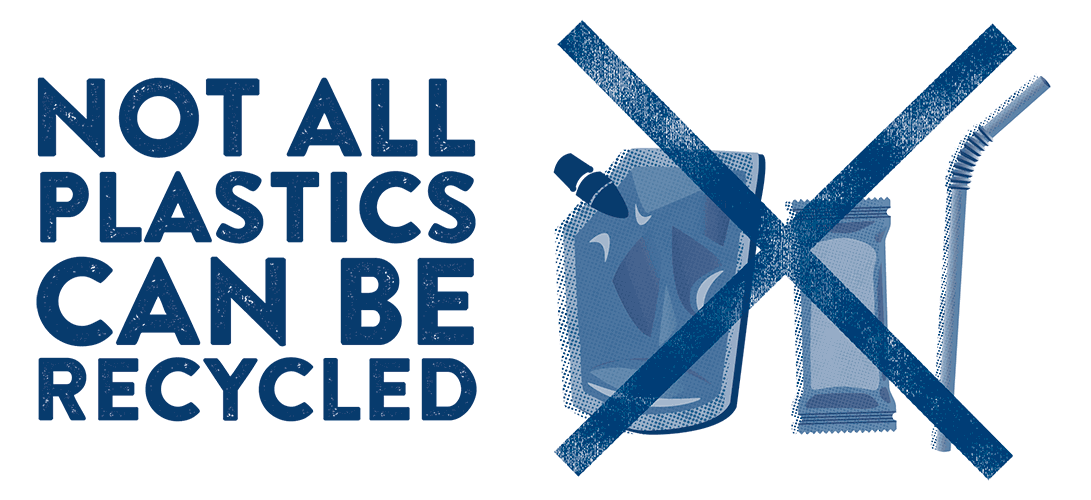

Recycling all depends on the technologies available to do so. Plastics that are able to currently be recycled are transparent PET (Hellmann’s Bottles & Jars material), PP and PE. However, flexible laminates (Doypacks and sachets) are not.

Every time PET plastic is recycled the material goes through a “downcycling” process, losing value. Eventually the plastic is unable to be reused again.

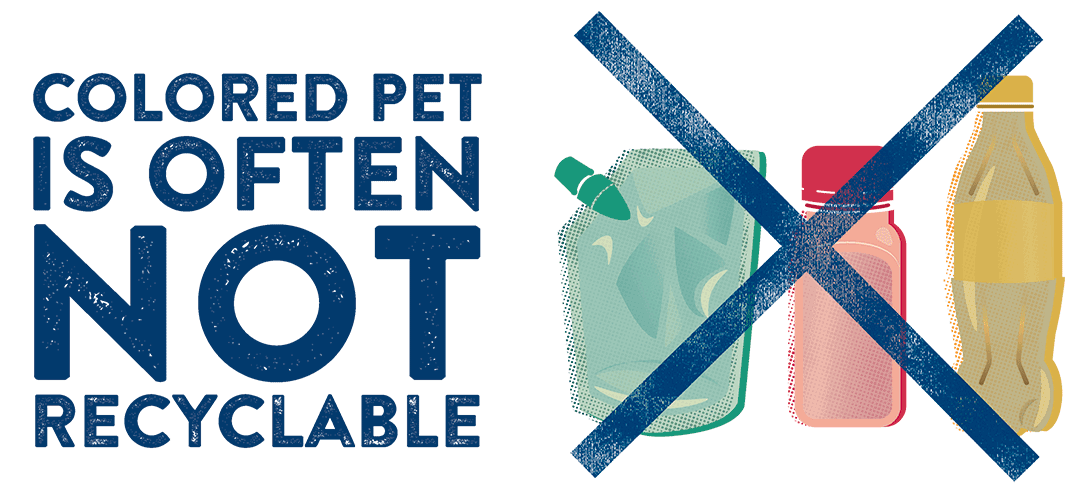

Recycling colored PET would result in dark opaque bottles with no commercial appeal, leading the recycling industry to often not collect them.

Food industry rigid policies for its plastic sourcing can make recycled PET production more labour intensive and restrict its plastic suppliers, making this material offer less abundant and more expensive.

See what we are doing about the plastics problem